The new recyclable materials concept

Focus on sustainability and resource conservation

At a time when sustainability and the efficient use of resources are becoming ever more important, Wipotec is taking a major step towards a sustainable recycling system. The planned new recyclable materials concept aims to reduce the volume of residual waste, conserve resources and focus more on recycling.

Wipotec currently produces around 70 tons of residual waste every year. Collecting this waste costs a lot. To tackle this problem, the company relies on the magic formula of sorting waste according to type. Various recyclable materials like paper, PE films, cartons as well as coffee and food residue should be collected separately. Collection points are installed around the production facilities and the offices to facilitate sorting of recyclable materials. Implementing this system has led to an impressive reduction in the volume of waste to around 47 tons per year and the number of collections has been reduced to 18.

Sorting recyclable materials by type also reduces the quantity of mixed scrap. Currently, around 25 tons are produced annually. In the first stage, this ratio is set to be reduced to approximately 15 tons. To achieve this, investments are being made in more chip carts and collection bins to sort scrap consistently directly at the machines. High-quality materials are thus kept in the recycling loop without the need for complex sorting processes. At the same time, transportation of mixed scrap to the recycler is almost halved. A key focus of the new recycling concept is three selected recyclable materials for which Wipotec is developing innovative solutions to optimize the recycling loop.

Recyclable material no. 1:

Carton

Every year 60 tons of carton are produced at Wipotec, which previously required 60 trips for disposal. To make these cartons recyclable the company is planning to purchase its own press. Pressing these cartons will produce more than 120 carton bales requiring only four collections every year. In future, some of the carton will be recycled on site and reused as packaging mate-rial. This action reduces the need for new packaging material and helps to further conserve resources.

Recyclable material no. 2:

Aluminum chips

The production of aluminum parts at Wipotec generates over 50 tons of chips per year. To reduce the approximately 33 collections, the company is planning to use its own aluminum press to press the chips into briquettes. The coolant adhering to the chips is removed so that the briquettes only have a residual moisture content of approximately 1 %. By pressing the chips, the company achieves a volume reduction of 1:6, thus reducing the number of collections to 10 a year. Furthermore, the recyclable briquettes can also be sold directly.

Recyclable material no. 3:

PE film

Polyethylene film (PE film) is a valuable recyclable material that previously ended up in the residual waste at Wipotec. The new concept envisages pressing PE film into bales at the plant and transferring them directly to the disposal company.

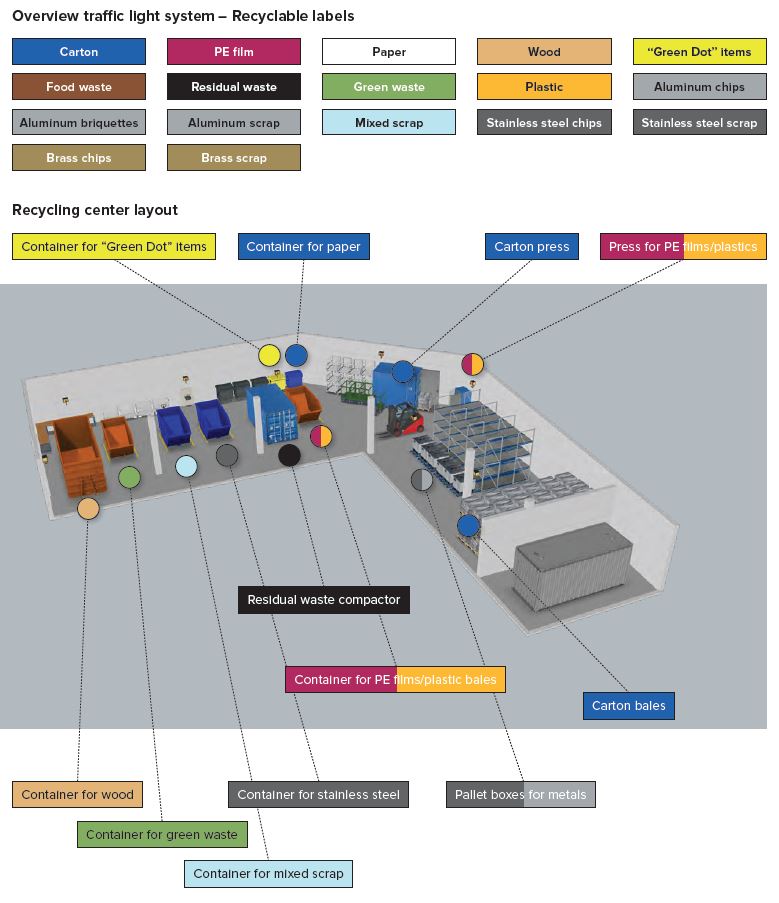

Introducing a traffic light system

To help employees sort recyclable materials, Wipotec has introduced a traffic light system, which gives a visual representation of the recycling principle. This serves to raise awareness for the recoverability of the sorted materials and the importance of sorting them according to type. To implement the new recycling system efficiently, Wipotec is planning to construct a recycling center where the collected recyclable materials can be stored and processed centrally.

The presses will also be located here. These presses process the recyclable materials for recycling and thus also generate higher returns. Wipotec’s goal is ambitious: a 70 % reduction of waste transportation per year and a reduction of the residual waste volume by more than one third. With this new recycling concept, the company is setting an example for sustainability, resource conservation and is making an important contribution to protecting our environment.