Advantages of our state of the art X-ray portfolio:

- Modularity enables fast development and integration of solutions

- Standard portfolio from entry-level scanners to premium combination units

- High-resolution HD-TDI camera detector technology in compact designs

- Intelligent software covering a wide range of applications

- Conformity with standards such as HACCP, BRC or IFS and others

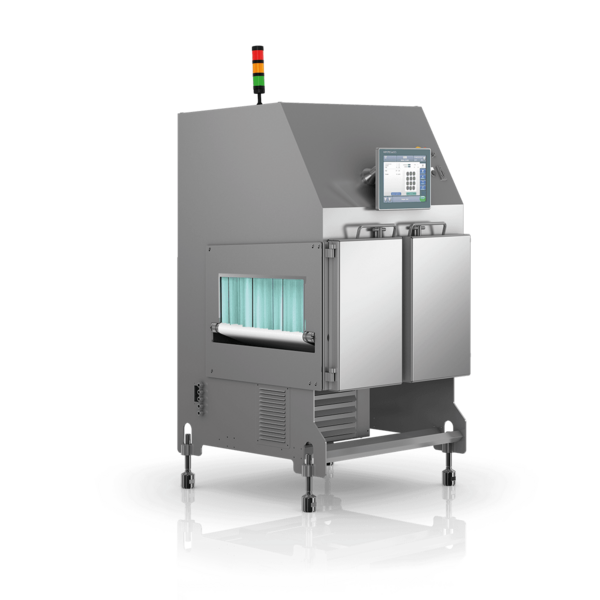

High-tech X-ray scanner for professional detection of contaminants

The SC-E is the perfect entry to the world of ultra-modern X-ray inspection systems and the associated high quality product line of Wipotec. Designed and developed to meet the most stringent requirements of foreign body detection, with an optional comprehensive software package, the scanner becomes an excellent all-rounders that reliably performs count, completeness, fill-level checks, and mass determination.

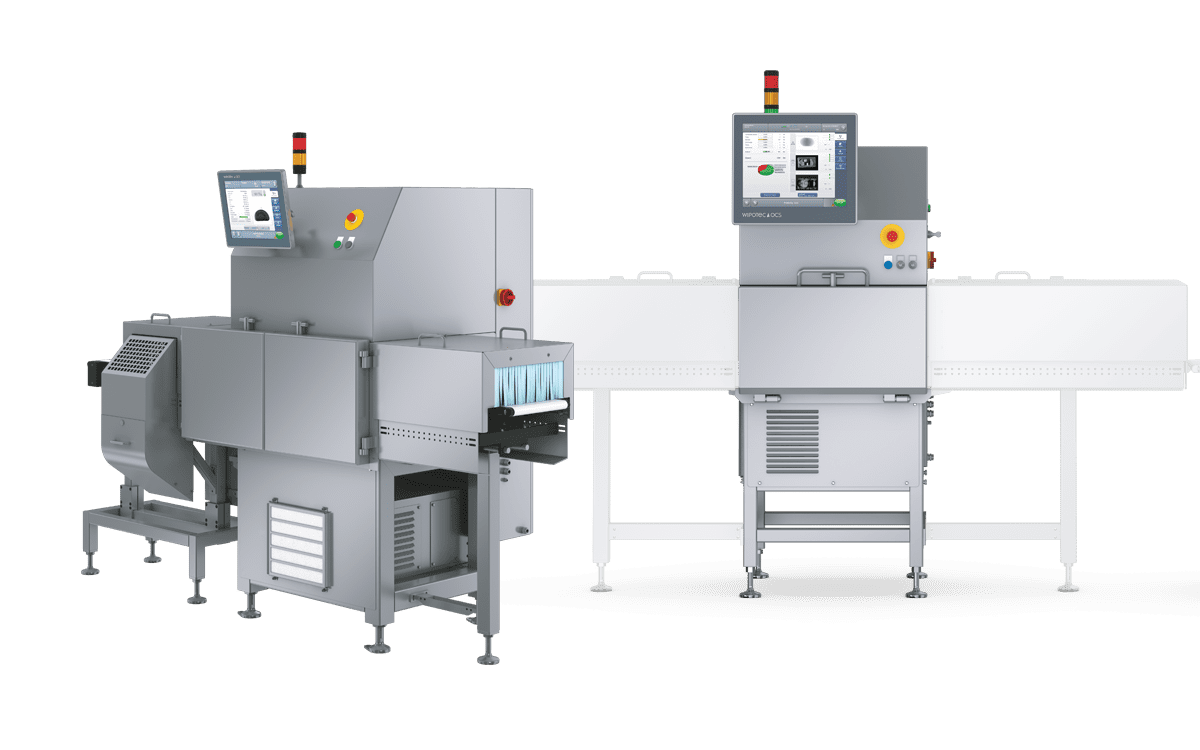

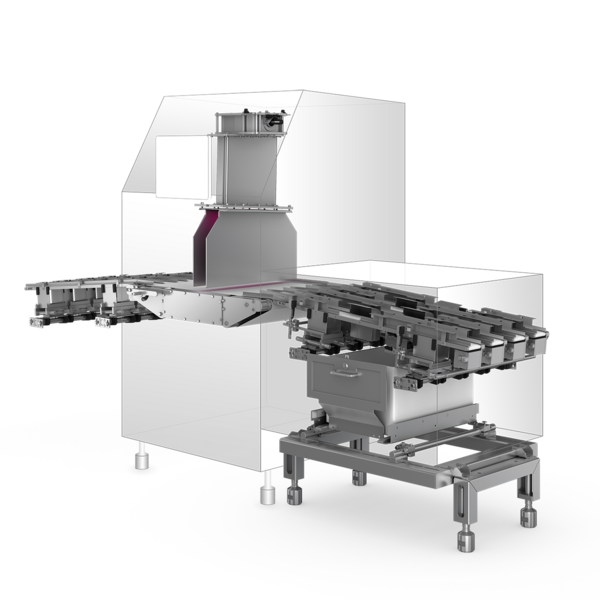

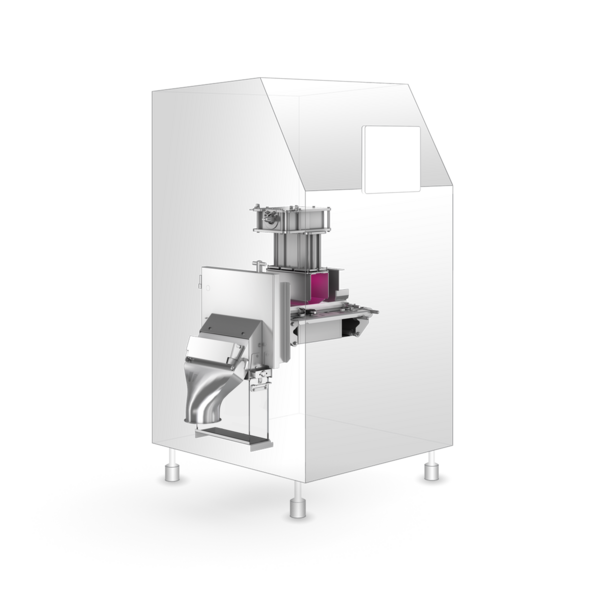

Even better together: X-ray & weighing or X-ray & vision inspection

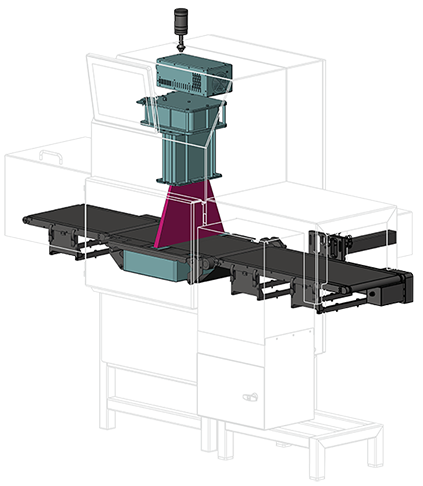

Particularly when there is little room, quality assurance still has to work as reliably and precisely as in large spaces. The innovation: a combination of two or three solutions. In each case, X-ray inspection food forms the basis which we expand with the option of a checkweigher (SC-W), a vision inspection system (SC-V) or a checkweigher and vision inspection system (SC-W-V) – whatever you need.

All in all, you benefit from the extremely space-saving version of two perfectly complementary inspection technologies. You notice it at the latest when you operate X-ray inspection and checkweigher via a common user interface.

With a maximum output of 300 packages per minute, you are always on the safe side, even in the multi-lane version. In addition to foreign body detection, this combination provides you with the best results of high-precision weight checking and simultaneous ejection of incorrect weight units.

A combination of X-ray inspection systems and vision inspection system is the ideal solution if your product requires a vision inspection from above and/or below in addition to foreign body detection. In this case, you have added value since the information printed on the product is also verified. And what’s more, the positioning and readability of labels can also be checked accurately. Another advantage: operation without curtains is possible. This makes the combination of X-ray inspection system and vision inspection the perfect solution for lightweight products such as mini cakes, biscuits or brownies.

Product details of the inspection systems:

SC-W: Checkweigher and X-ray inspection

Modular concepts are the basis for the most individual X-ray solutions

To allow us to guarantee the most accurate X-ray inspection food in your production, we have designed our technology so that it is inherently capable of creating the product gaps needed for the inspection. As a result, the products detected as defective during the inspection are removed from the current product flow using optionally available ejection mechanisms.

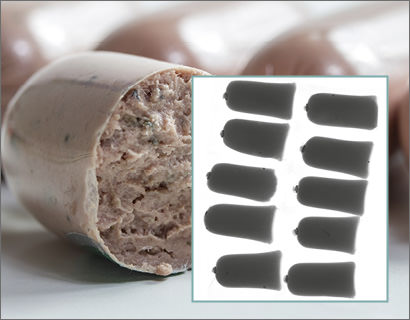

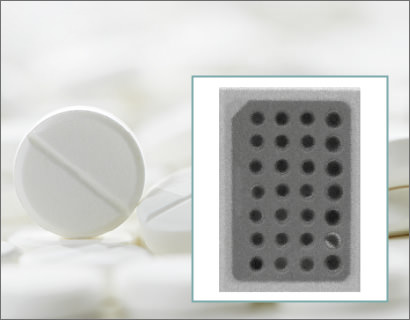

Your benefit: reliable detection of contaminated products and immediate removal from the batch. Our portfolio includes a wide range of air-cooled monoblocks or water-cooled metal-ceramic tubes with beryllium windows so that we can offer you exactly what you need for your individual process and your specific product. Diode line and camera detectors with HD-TDI technology are used as sensors. You benefit from reliable detection of a wide variety of foreign bodies such as electrically or magnetically conductive particles as well as glass, stones or plastic.

Optimally adjusted, it is thus possible to achieve false rejection rates approaching zero, even with high product numbers and speeds. And the fact that our X-ray inspection equipment finds even the smallest impurities in the product is another strong argument in our technology’s favour.

Powerful X-ray technology from Wipotec

The prerequisite of a successful detection of foreign bodies are X-ray images of the highest quality. It begins with the selection of the optimal X-ray source in combination with the best sensors and high performance image processors running the software.

The modular system of Wipotec X-ray technology encompasses air-cooled monoblocks as well as water-cooled metal ceramic tubes with beryllium windows.

The resulting high resolution X-ray images correspond to the specific density profiles of the controlled products. Foreign bodies within the product are then detected on the basis of their higher specific densities.

The X-ray images are displayed in real time on the 15” touchscreen control panel. Simultaneously, by means of in-house developed image processing software, they are checked against a number of possible defects like impurities, product deformation, fill level deviation, and incomplete or broken products.

Defective products are removed from the production flow with the aid of any one of a variety of alternative mechanisms. The ejection crosscheck control (optional) reliably monitors this process. In the interest of full traceability, the images of the ejected products are archived with a date and time stamp in the image data memory.

VioX camera technology from Wipotec

In this video Joachim Ott, Business Development Manager Product Inspection at Wipotec presents SC 40 X-ray scanner with built-in VioX TDI camera.

SC 40 X-ray scanner video: Joachim Ott, Business Development Manager Product Inspection, explains the VioX TDI camera of the SC 40 X-ray scanner from Wipotec. The camera, with a resolution of up to 0.1 millimetres, detects even the smallest foreign objects. The integrated X-ray trap completely protects the electronics from X-ray radiation and prevents wear. This means maximum reliability for electronics inside the VioX camera.