Your Trusted Dairy Inspection Solutions: Maximize Your Customer's Satisfaction

Our checkweighers and X-Ray inspection machines have been hard at work for years earning the trust of dairy companies like yours. These dairy inspection solutions accomplish three major goals:

- Maximize Your Customer's Satisfaction

- Minimize Product Waste

- Lower Costs While Eliminating Recalls

Efficient and error-free product inspection of dairy products accomplishes these goals. Checkweighers ensure that your customer's get what they pay for, while preventing wasteful product overfill. X-Ray and OCR vision inspections ensure that your dairy products are free of foreign bodies, and that the packages are properly labeled thereby eliminating expensive product recalls. See how you can improve the quality assurance of your dairy products with our proven weighing and inspection solutions.

On this page you will find more information about:

E-paper: Your Trusted Source for Dairy Inspection - Cheese and Yogurt Production ROI Examples

Live-Webcast: Quality control of dairy products

For a safe and cost-effective production line

In our exclusive Webcast our experts discussed solutions for a filling and packaging line in order to improve safety and efficiency. Emphasis was made of the weigh cells, checkweigher and X-ray systems.

Are you interested in reducing the number of rejections that originate from over or underfilled containers? Could your foreign body detection system be more reliable?

Do you build machines for dairy filling and are looking for reliable calibrated weigh cells?

Perhaps this may sound like a future innovation, but these systems already exist for dairy filling and packaging.

Would you like more information about weighing, checkweighing and X-ray options for dairy production? If so, we would highly recommend that you contact us, or to begin with watch the recording of our Webcast!

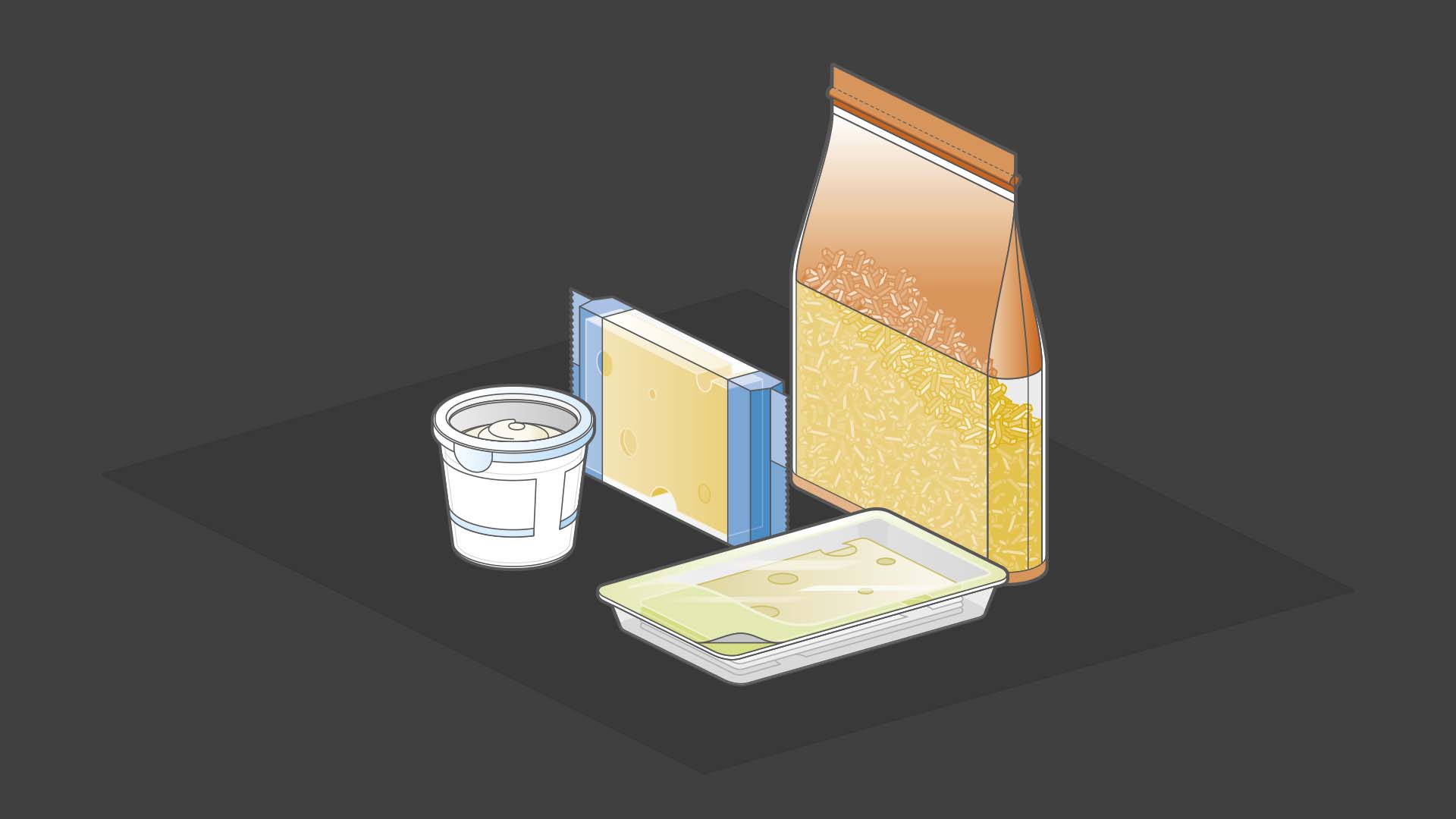

Download E-paper: Product Inspection of Dairy Products Using Cheese as an Example

Find out in our e-paper what options are available for inspecting your cheese products and where you can ideally use product inspection solutions in your line to guarantee 100 percent quality. Depending on the type of packaging, we focus on the most popular, and condition, there are a number of specific applications, such as ripeness determination of the cheese block or heat-sealed seam checking of pouches.

You can also learn more about the advantages of our high-performance checkweighers and modular X-ray scanners with specific reference to your production scenario.

Challenges in the production of dairy products

- Our entry-level X-ray scanners and the SC series quickly and reliably detect foreign bodies, such as fragments of glass, stone or metal, in dairy products. These products are automatically ejected from the product flow.

- Our automatic ripeness detection can not only determine the degree of ripeness from the X-ray image, but also whether the holes in the cheese are evenly distributed. As a result, there is no need to halt the ripening process if the cheese is not yet ripe.

- Our X-ray scanners can inspect 2- and 3-layer crates, filled with yoghurt pots for example, all at once. The result is a higher throughput rate.

- Dynamic checkweighers of the E-M-A series reliably detect underfilling or overfilling and additionally communicate with the filler to adjust the quantities in the event of fluctuations. You can protect your image and increase the efficiency of your production at the same time.

- Humid environments and strict hygiene regulations are frequently challenging for producers. Our X-ray scanners and checkweighers (-VA and -WD series) have been developed for light and deep cleaning cycles. They comply with protection classes up to IP69K and meet all the legal requirements of the food processing industry.

- Our SC-S side-view scanner scans horizontally. The X-ray camera is height adjustable (option) so that large and small cylindrical containers, such as milk cartons or bottles, can be fully inspected, thus guaranteeing the quality assurance of your dairy products.

- The SC-V X-ray scanner with integrated vision inspection can identify missing or incorrectly printed and positioned labels. You can thus ensure that all information (best before date, allergens, barcodes, etc.) on the product is legible.

We are happy to advise on how you can optimize the safety of your dairy products with our weighing and inspection solutions.

The advantages of our checkweighers for the inspection of dairy products

- Wipotec EMFR weigh cells permit throughputs of up to 650 pcs/min

- Demand-oriented modularity for tailor-made applications

- Exact filling results for reducing the TCO

- Easy, user-friendly operation

- GMP conformity and hygienic design

Our combination devices are ideally suited for inspection in compact spaces.

The SC-W combines our high-precision checkweigher with the modular X-ray scanner. The HC-M-MDi checkweigher additionally offers an integrated metal detector on the smallest footprint. For the heavy-duty and secondary packaging sector, the HC-M-SL is an excellent solution..

The advantages of our X-ray scanners in the inspection of dairy products

- Modularity of the SC Series permits fast, flexible solution development and integration

- Broad range from entry-level scanners to high-performance combined devices

- High-resolution HD-TDI camera detector technology in compact designs

- Optimal application implementation via intelligent software features

- Conformity to standards such as HACCP, BRC or IFS and others

- 16-bit camera technology

- Camera detectors with up to 102 µm resolution and multi-resolution

- Inspection speeds up to 2 m/s

Webinar: Product Inspection of Cheese

Our free 30-minute webinar tells you everything you need to know about quality assurance measures during cheese production. Our experts also explain the uses and economic advantages of high-performance checkweighers and modular X-ray scanners as well as discussing the most popular types of cheese packaging.

Presenters:

Joachim Ott, Business Development Manager Product Inspection

Sascha Wenz, Product Manager Checkweighers

Member of the European Hygienic Engineering & Design Group

Foreign body detection, ripeness determination and compliance with hygiene regulations are particularly important in the product inspection of dairy products such as cheese. We specialise in this and can offer you the whole range of product inspection for dairy products from a single source. With cheese, for example, our inspection systems check your product from shaping and cutting to secondary packaging. For all dairy products, we ensure compliance with the regulations for consumer protection, packaging, inspection standards and efficiency and help you not only to strengthen your brand with seamless product inspection but also to ensure long-term customer confidence.

There are strict standards for food safety that are designed to maintain consumer confidence. These include the EU Packaging Directive, the HACCP concept (risk analysis and critical control points), the IFS (International Food Standard), the BRC (Global Standard for Food Safety of the British Retail Consortium), the FDA, the GFSI certification (Global Food Safety Initiative) and others.

As a member of the European Hygienic Engineering & Design Group (EHEDG), we are particularly committed and experienced when it comes to the production and packaging of food. We are happy to advise you on all matters regarding standards in the food industry and product inspection for the quality assurance of dairy products.

We specialise in the product inspection of dairy products. Checkweighing, foreign body detection in dairy products, automatic ripeness determination, label checking and more: with us you get all the solutions from a single source.

Our X-ray inspection solutions (SC series) and checkweighers HC-M-VA and HC-M-WD for dairy products are at least protection class IP65-compliant in the product space and therefore meet the strict requirements of the food industry.