Reliable 360° Inspection for Semi-Automatic Aggregation

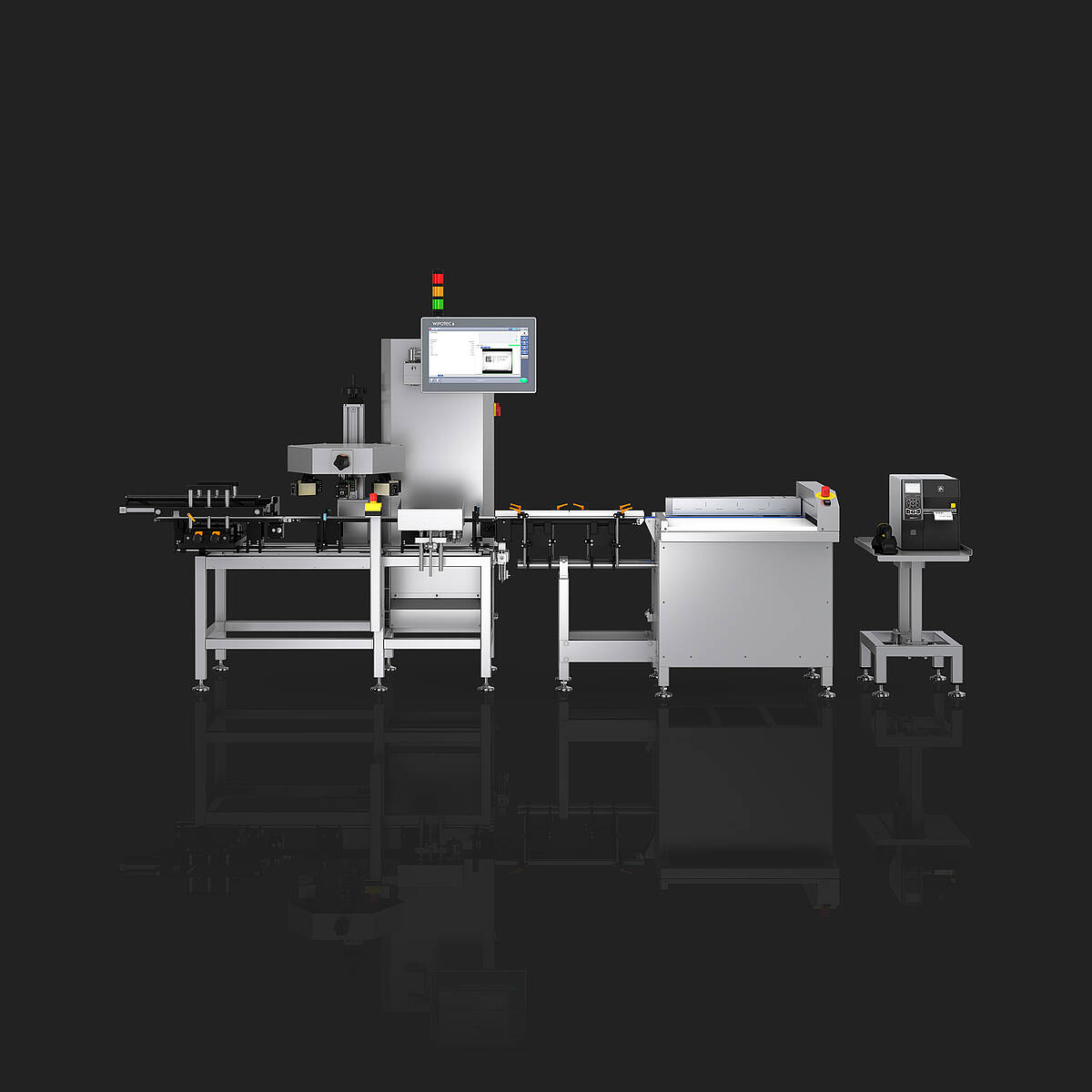

TQS-CP-Bottle is designed for the perfect integration in bottle or vial production lines. The system can be set up directly at the outlet of any conventional labeling machine to verify the previously serialized labels on individual cylindrical containers via an omnidirectional, 360° inspection.

This is done by a 360° camera, which features a central adjustment unit to facilitate the tool free adjustment of all cameras to the respective diameter of the bottles.

Bottle-shaped products are transported to the machine via a conveyor screw. The codes of previously serialized products are identified in a 360 degree process. A non-readable or invalid serial number leads to its discharge. The products are then collected up to the target amount for the carton and handed over to the operator for packing. Once the carton is full, the operator applies the automatically printed label to the shipment carton and verifies it with the handheld scanner.

Key Features

- Integrated 360° camera module for ultra-fast inspection (aggregation)

- Secure product handling and separation of cylindrical objects through infeed screw for superior inspection results

- Semi-automatic aggregation of serialised bottles into shipment cartons

- Validation packets and documentation IQ/OQ, FDS, RA, TM

- Tool free format change

- Fastest configuration with ConfigureFast

Further Information on the Topic of Track and Trace

Semi-automatic bottle aggregation

TQS-CP-Bottle at HANA Pharm. CO. LTD. is set up directly at the outlet of a labeling machine. Codes of previously serialized HDPE-bottles are verified via an omnidirectional 3600 inspection. Bottles are collected up to the target amount and handed over to the operator for packing.