No Ifs or Buts: Product Inspection and Inline Quality Assurance

If your manufacturing and packaging processes are all about speed, inline product inspection is the only choice for your quality assurance. Properly integrated into the process, our product inspection systems enable you to achieve the highest speeds and the best quality – on an ongoing basis.

You know that, for the individual inspection of your products, you have only seconds for precise transport, positioning and inspection. With our weighing systems, you are therefore optimally positioned in terms of quality assurance and performance. The fact that we always keep an eye on all legal regulations and that, thanks to the latest technology, you pass every completeness check with flying colours and can quickly detect underfilling and overfilling, speaks in our favour. And also in yours as a food producer.

And just in case you prefer vision and X-ray inspection systems or metal detectors, there too we have the latest technologies in our portfolio.

It goes without saying that we think ahead and design our combination machines consisting of checkweigher and X-ray inspection system in such a way that you can also retrofit them if you wish. It’s obvious too that we design our systems to be as compact as possible and thus take your spatial limitations into account.

Want to inspect your products at the highest level?

Indispensable Inline: Dynamic Checking and Product Inspection Systems

Weighing Miniscule Quantities: Quickly and Accurately – a Herculean Task

Both deliver precise results even for just a few grams of filling volume and are therefore ideally suited for 100% product control. By measuring with our weighing technology, it is possible to determine the weight in each case.

At the same time overweight and underweight products can be ejected or the fill quantity adjusted. And the fact that you can use our technology to exert a decisive influence on subsequent processes and quality assurance is probably the strongest argument of all in favour of our weighing technology.

Checkweighers for dynamic inspection processes

Does your production process rely on optimum monitoring of a wide range of weight criteria for different products? Our dynamic checkweighers do just that, monitoring your goods inline with a large number of parameters while the belt is running and ejecting any of incorrect weight. Optional optimization of the filling quantity in upstream dosing, filling or cutting systems is yet another key benefit.

The Weigh Cells used act as weight sensors and operate on the principle of electro-magnetic force restoration (EMFR measuring principle).

Product Handling – Sometimes a Top-Heavy Matter

Do you manufacture products or specific types of packaging that are top-heavy, have a small footprint or an unfavourable height-to-width ratio? You want to inspect bottles, pouches, cans or cartons at high speed? Thanks to our expertise and experience our technologies are individually tailored to your products and process requirements and handle your products competently. We have developed solutions which separate your products and then transport them safely to the weighing belt before discharging them again.

We use separating belts, screw conveyors and rotary star wheels to meet your quality requirements in full. The fact that we can also implement complete line integration via the synchronised motors of conveyor belts in the production or packaging machines and checkweighers says a lot about us and our expertise.

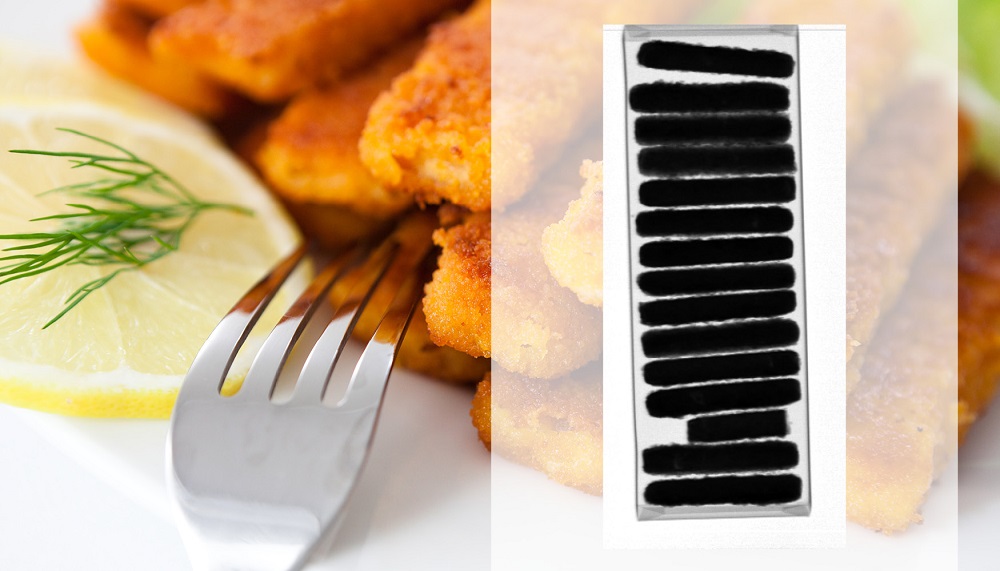

Providing an Inside View – X-ray Inspection Systems for the Inspection of Food

Whether as a replacement or sensible addition to your production, X-ray inspection systems, also known as X-ray scanners, are now essential in many applications. Their versatility makes them all-rounders that can cover conceivably the broadest range of detectable materials and products. X-ray inspection systems are a must if you want to inspect the inside of your goods quickly and reliably.

Another strong argument in favour of X-rays: they are much more efficient at detecting extremely homogenous environments, such as bulk goods (rice) or lumpy goods (chicken nuggets). If you manufacture within these production parameters, choosing X-ray inspection equipment means you are also choosing high detection speeds with maximum sensitivity.

In addition to detecting foreign bodies, you can perform additional tasks such as checking and complying with fill levels or monitoring shapes, position or dimensions. X-ray inspection systems also score points for their ability to count products, check the distribution of ingredients in foods, control the seal-tightness and integrity of packaging and seals and, last but not least, to find damaged products.

We make all these tasks very easy for you: a wide range of imaging technologies complete the X-ray inspection systems and direct them perfectly to the product to be inspected. This starts with imaging for flat products or bulk goods and extends to upright bottles or other cylindrical containers.

To ensure maximum flexibility in your production, the X-ray scanners can be combined with vision checking systems for product inspection from above and/or below. In this case, you clearly get added value because combining two technologies increases the scope of inspection tasks that can be carried out. Starting with foreign body detection and extending to verifying broken products and checking product dimensions.

Ultimately, when using X-ray inspection systems, you have the advantage of being able to capture your product dimensions precisely: length, width and height as well as the length of the outer packaging and of course also checking for integrity of the seal.

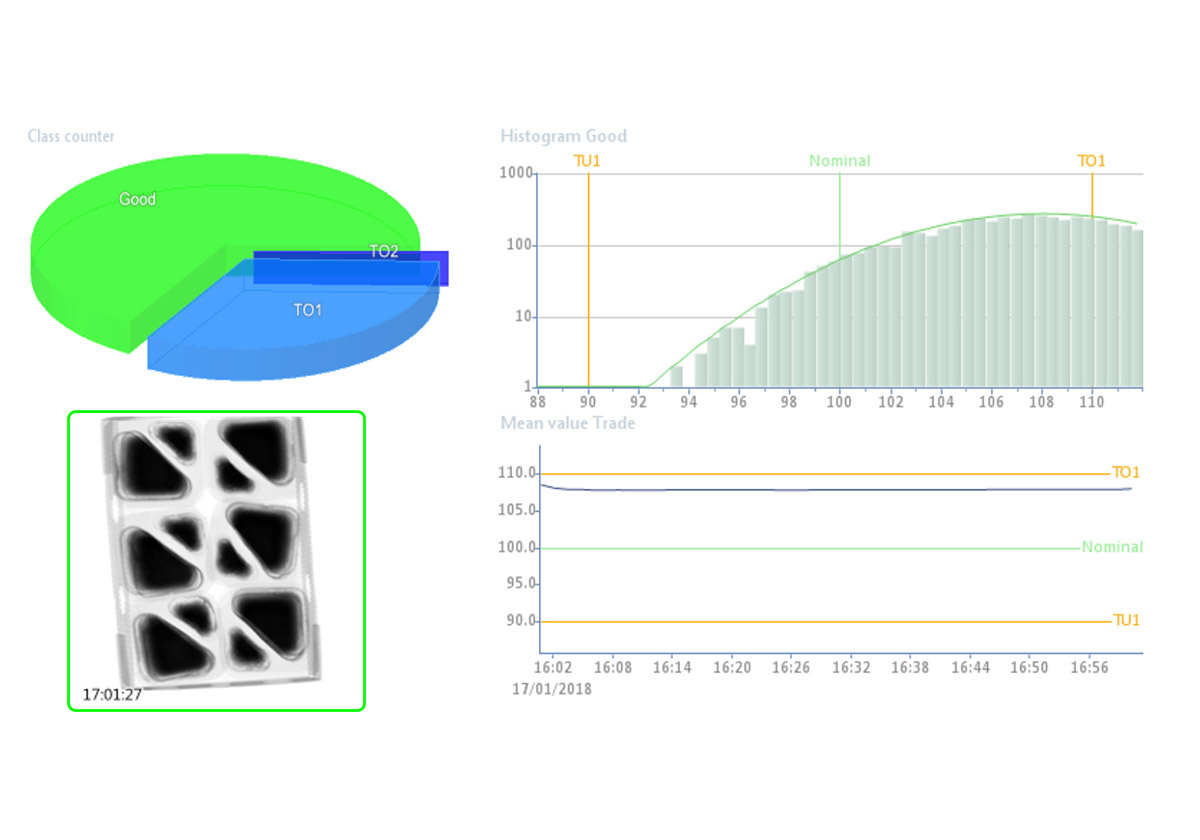

Food Product Inspection – Each System with its Own Software

Quality management only works 100% if you have all the data at your fingertips – quickly and accurately. To provide you with all the results from the inspection system we developed a management software – the so-called inspection data management. We bundle data from various types of your inspection systems (checkweighers, X-ray inspection systems, metal detectors). This gives you access to all inspection data within a company – across all sites and in real time.

A strong argument in favour for such a system: it allows you to collect and archive all data, making it easy for you to create reports, analyses and statistics.

Want to compare past production data with actual figures? No problem. The inspection data management does this as competently as viewing production figures, waste information, machine utilisation rates or product quality information. Information management is also the best choice if you want to track all data and events or link everything to an alarm system: no more tedious on-site checks. You can organise all your operations even more effectively.