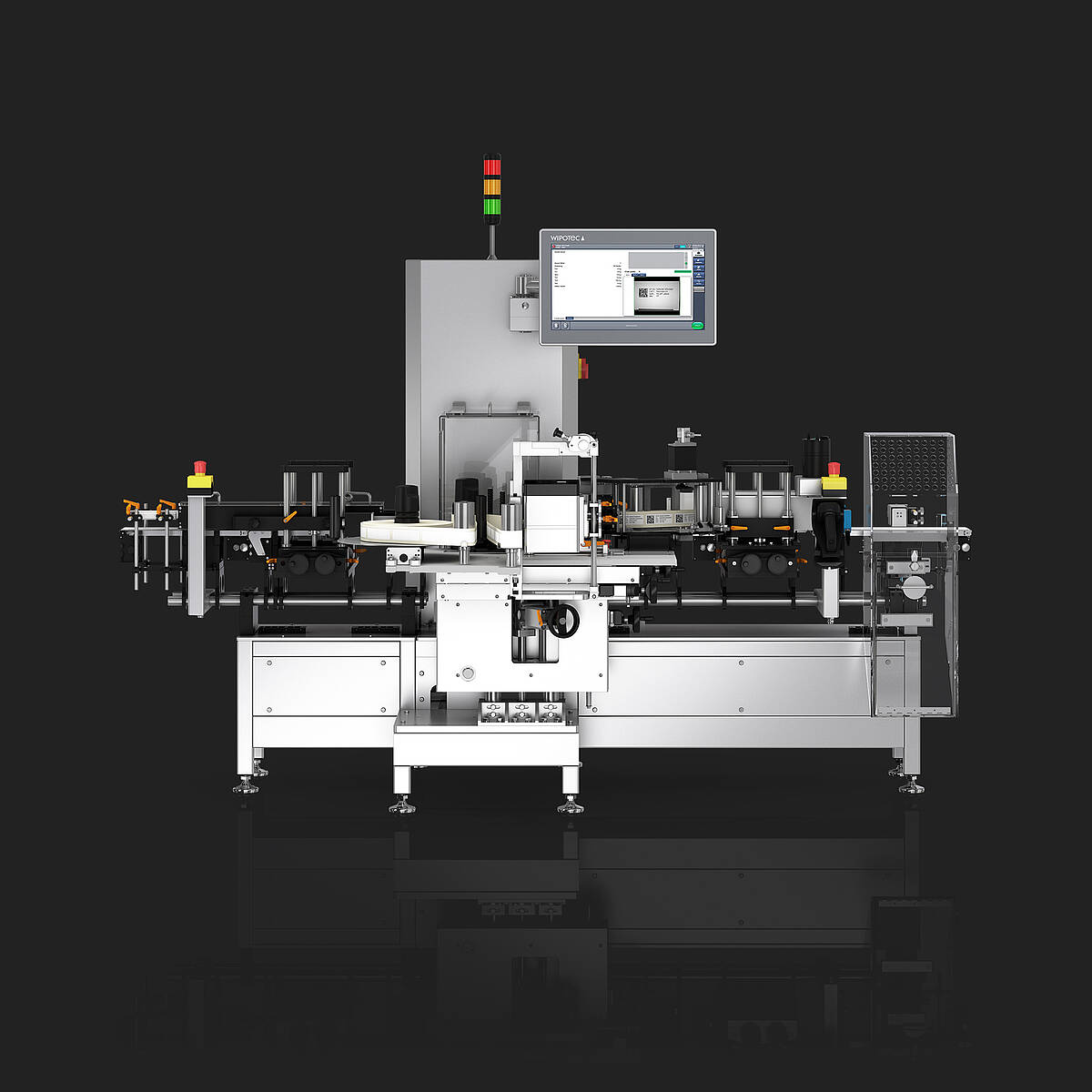

Serialisation for bottles and vials

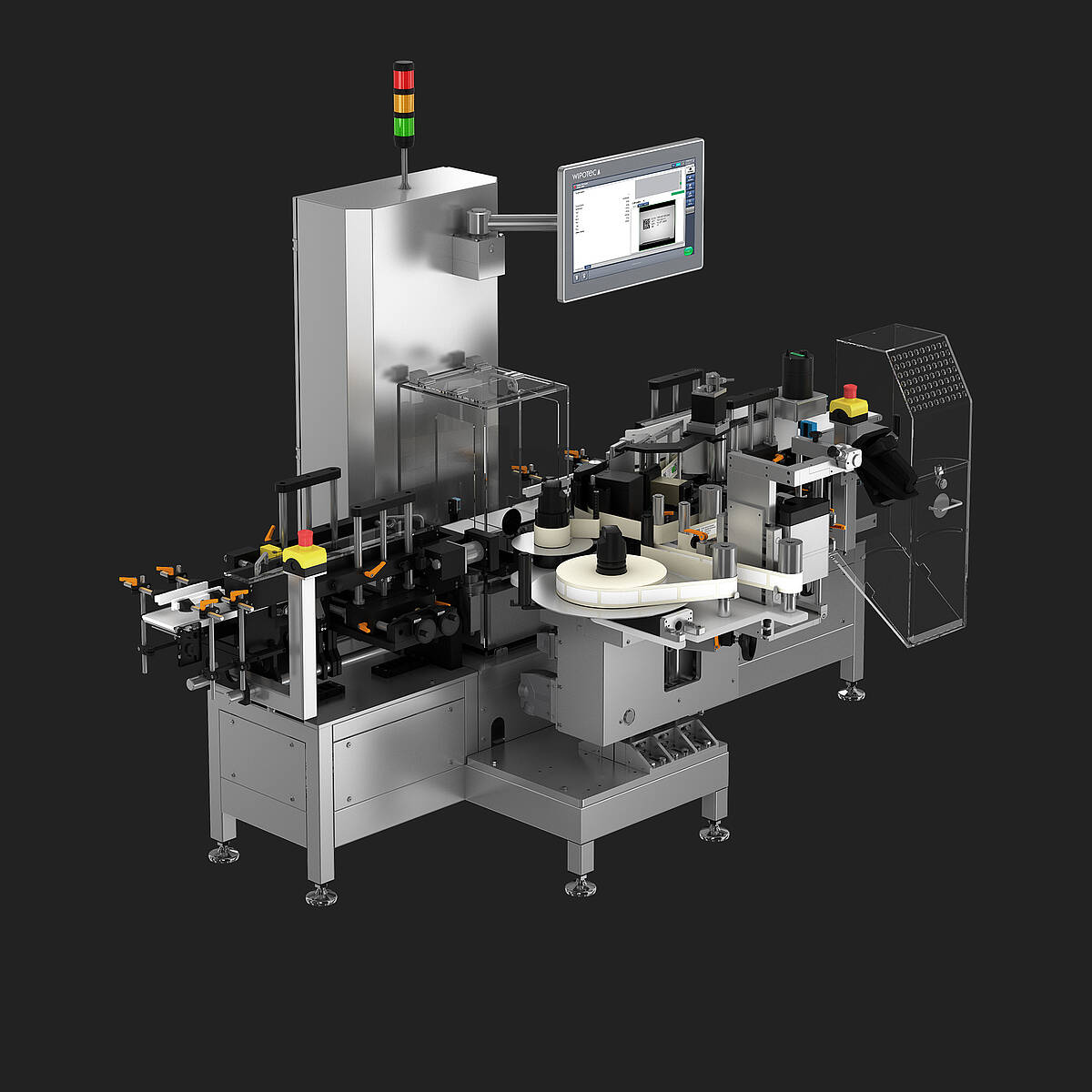

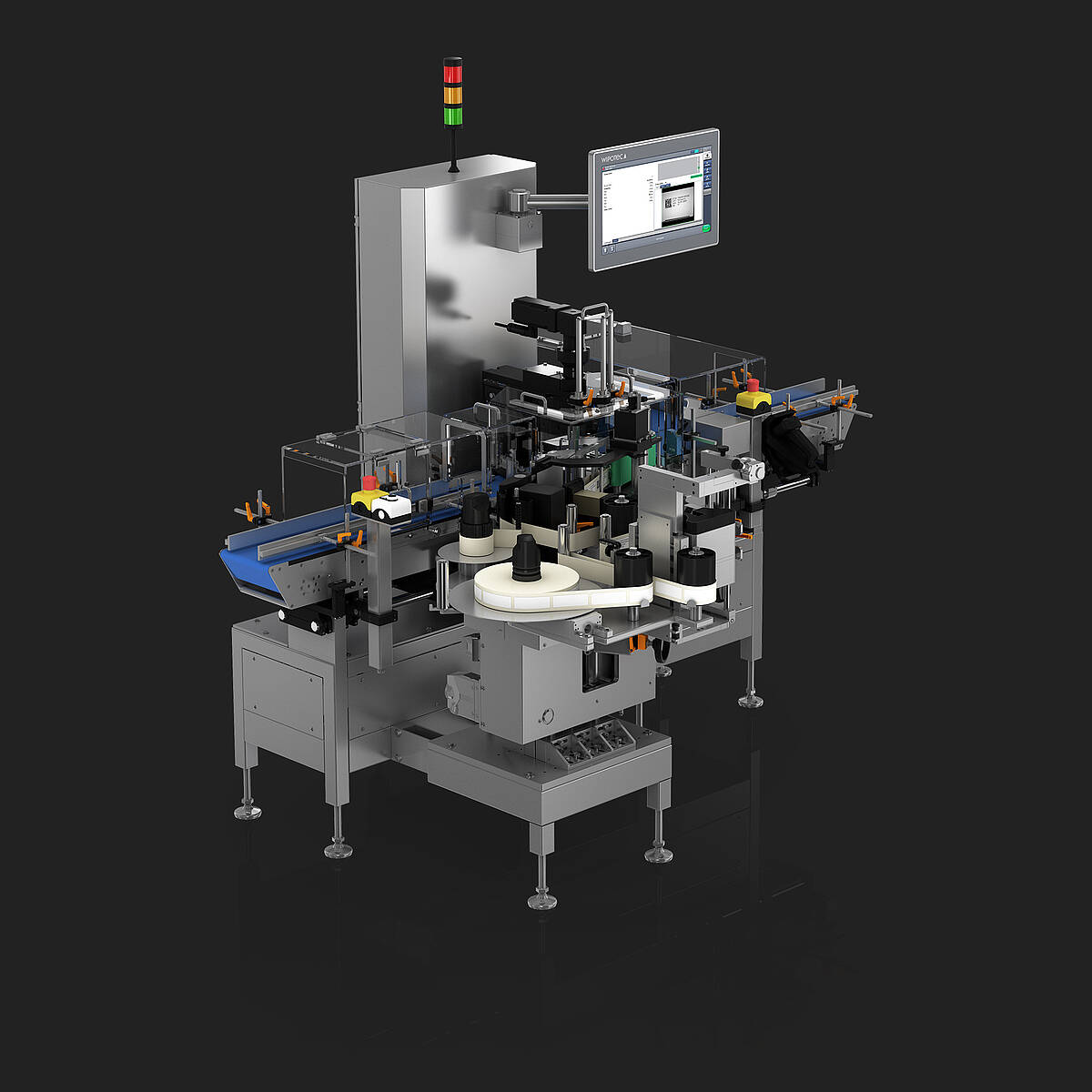

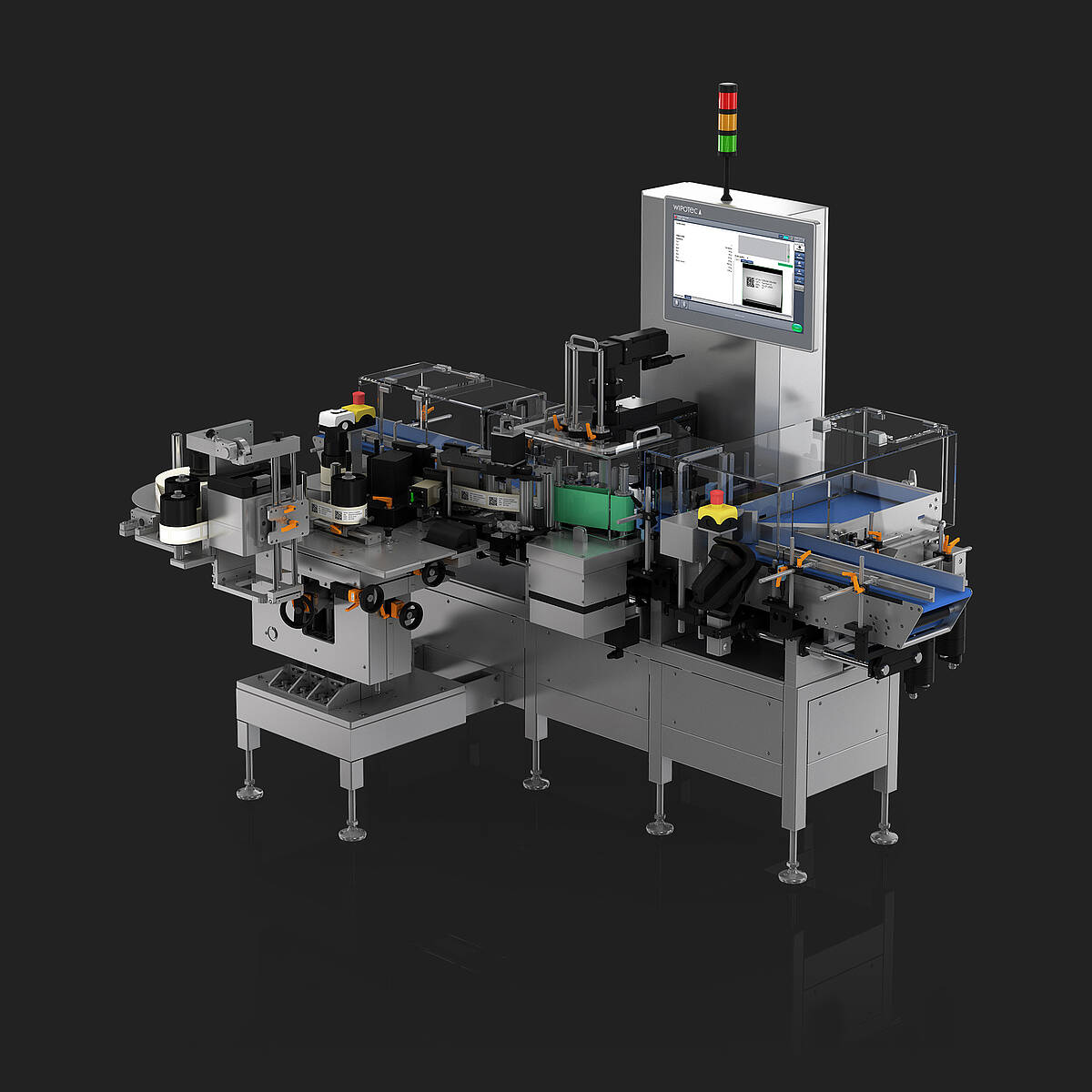

The TQS-Bottle from Wipotec serialises medicine bottles at high transport speeds. Serialisation is carried out simply by applying labels to the bottles. The compact, space-saving footprint of the TQS-Bottle combined with a very short design in the direction of product flow makes it easily integrated into existing lines. Labelling is carried out in a star wheel with format-specific pockets or a driven lateral side grip conveyor. If necessary, the system can respond to product-specific requirements with the aid of format parts. A thermal printing system ensures high-resolution printing of the labels with plain text and product codes.

Key Features

- Safe product transfer due to modular construction, different versions possible

- Thermal transfer printing system for high-resolution printing of plain text and product codes

- 100% correct labels due to full-surface optical print verification

- Ejection of faulty labels

- Return of unlabelled products to the process

- Large 15” with touchscreen display and intuitive control menu (19” optional)

- Can be optionally equipped with precision weighing system

Your benefits

- All-in-one operating concept for very quick and easy handling

- Space-saving design for easy integration into existing lines

- High throughput

- Large product range due to modular configuration

Digital control of the print head allows updating of the information to be printed without having to stop the system. The labels with or without booklet are applied centrally with the utmost precision. Readability of the printed information is optically verified full-surface before the labels are applied so that only 100% correct labels are used.

Any faulty labels are removed before the application process. Any unlabelled products can be returned to the process. Optionally, the TQS-Bottle can be equipped with a precision weighing system and is suitable for a large range of different bottle shapes and sizes. All components are operated on a central 15” touchscreen.

Further information on the topic of Track and Trace

TQS-Bottle: Compact serialisation solution for bottles and vials

Label printing and full-surface print verification paired with automatic labelling guarantee maximum process reliability. Faulty labels are identified and sorted out before application to ensure that only correct labels are applied. This unit can be integrated to any packaging line.