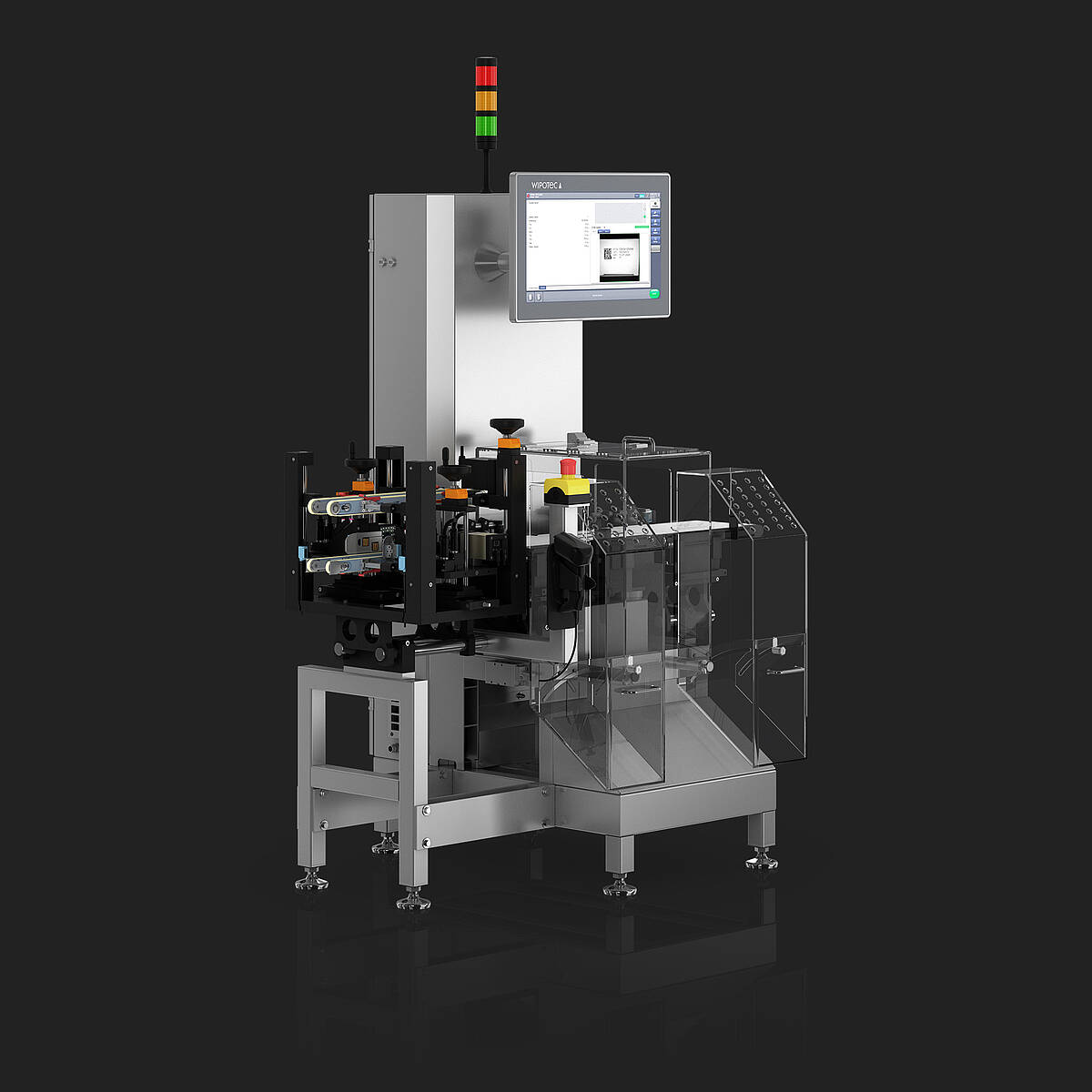

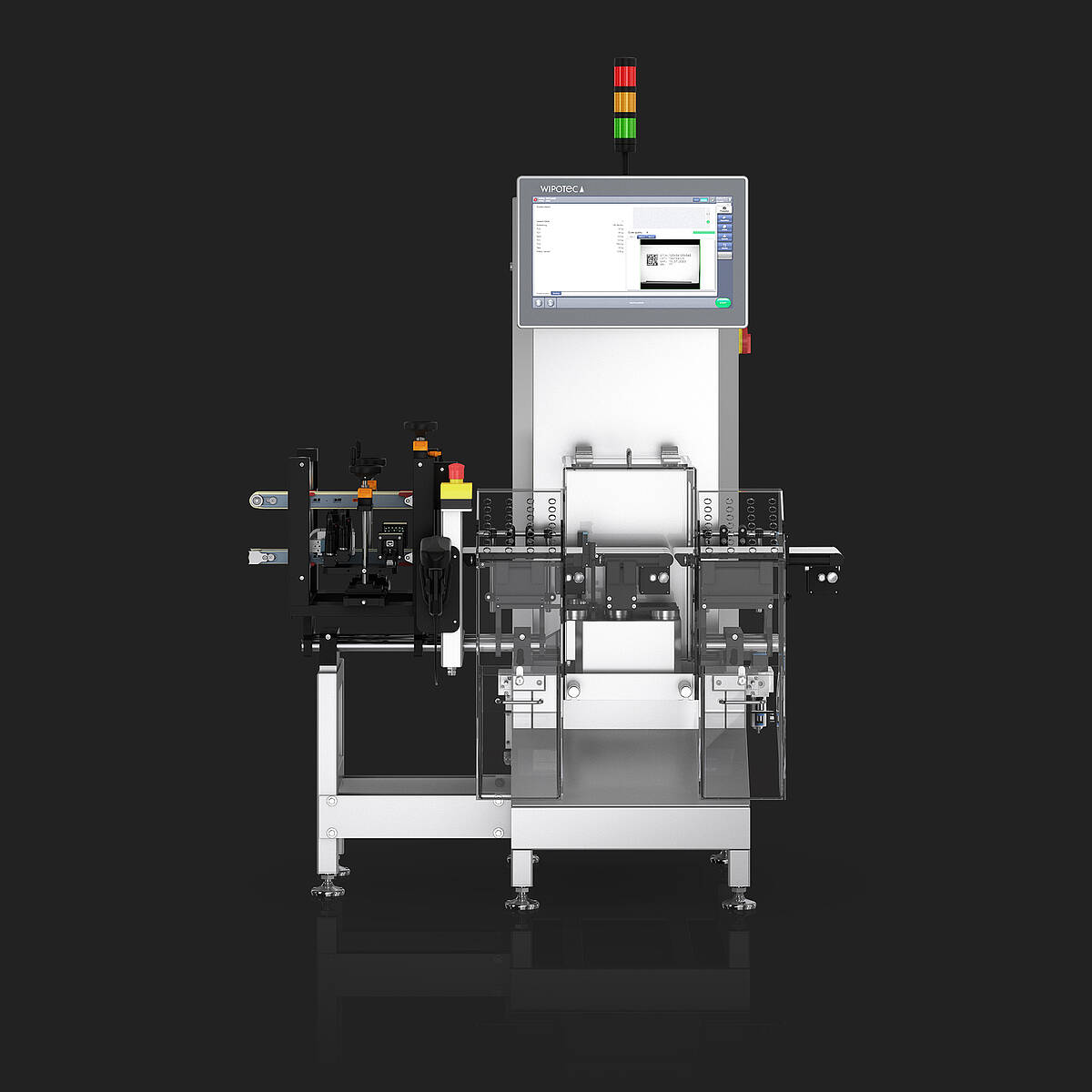

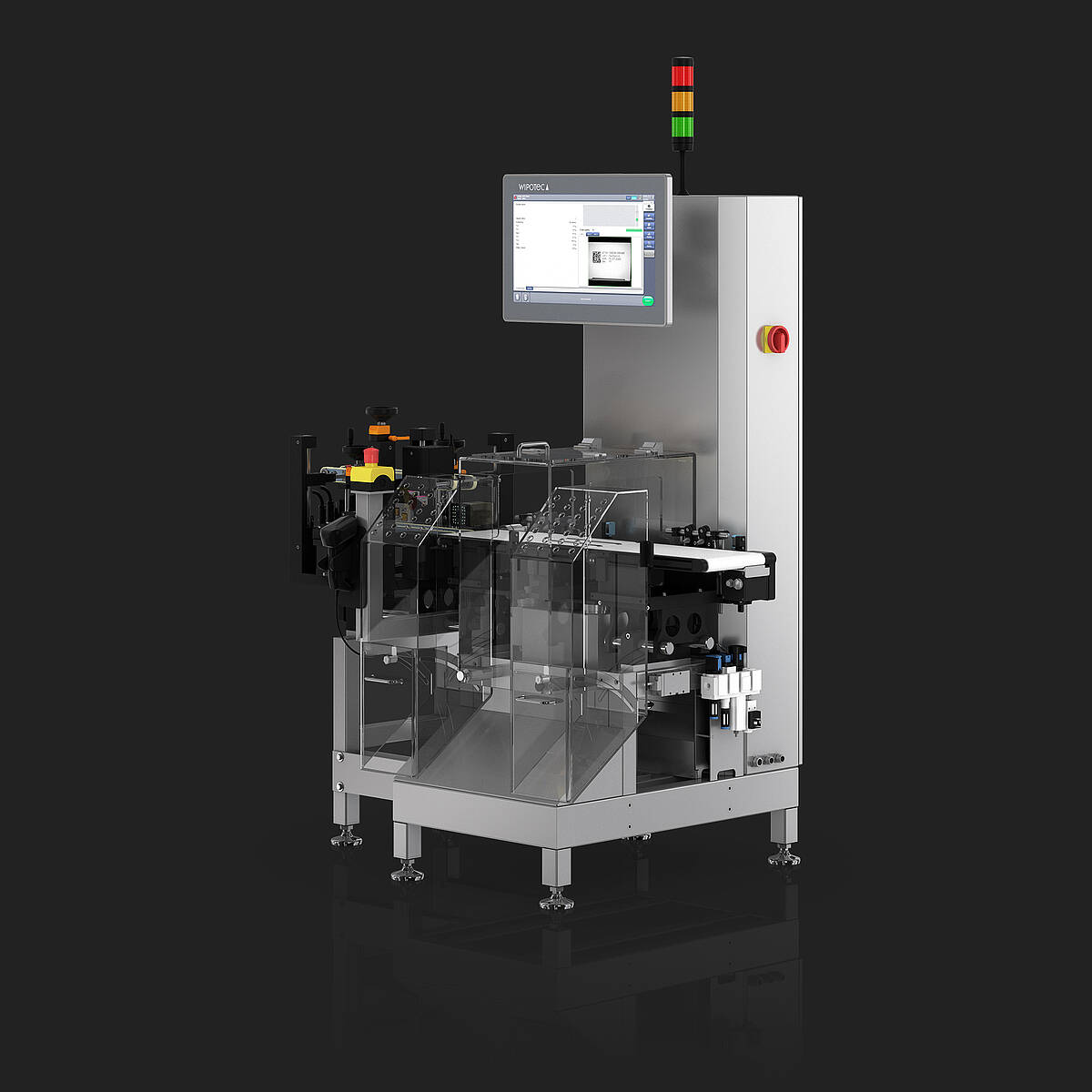

Serialisation and weight inspection – customised for your needs

TQS-HC-A adopts the convenient features of TQS-SP in terms of product management and serialisation, expanding them with a final completeness check by means of weight. Optional modules integrate the functionalities of our compact Tamper-Evident technology and country-specific vignette applicator.

The folding boxes are received from the upstream cartoner over a perfectly synchronised, adjustable top belt. This high precision product transport is the basis for smoothly guided coding and final verification. Products with faulty codes are discharged into a separate, lockable container in front of the weighing belt. Products with a faulty weight use a second ejection system directly behind the weighing belt. Thanks to ConfigureFast, identical print data is sent directly to the printer and to the camera‘s print imager; all system components are quickly and easily controlled from one single user interface without having to switch programs.

Key Features

- Highly precise product transport

- Fastest configuration with ConfigureFast

- Flexible print head / camera mounting position

- High-tech Weigh Cells from Wipotec for high precision weighing

- Large 15” touchscreen display and intuitive control menu (19” optional)

- Validation packets and documentation IQ/OQ, FDS, RA, TM (optional)

- Tool free format change

Your Benefits

- All-in-one operations concept for quick and easy handling

- Compact, high-tech, multi-functional unit for optimal productivity

- High throughput rate of up to 600 pcs/min (300 pcs/min is standard)

- Maximal integration flexibility through modular design