Smart Prediction of Weighing Accuracy in Sorting Centres

The sorting centre performance of postal and logistic companies is often affected by two problems – the industrial scales that have to be set up on platforms in sorting facilities, and vibrations of the construction due to the movement of parcels, conveyors or transport vehicles. These issues affect weight measurements, impairing scale accuracy and leading to higher calibration values. Accurate assessment of these specific conditions and their impact on catchweigher performance is the first step towards improving weighing precision and lowering calibration values. This step is now possible with the D-Box, a mobile diagnostic system for precise estimation of weighing accuracy in sorting centres.

On this page you can find out about our services and solution for analysing potential weighing accuracy in sorting centres:

Determining achievable weighing results and calibration values on-site

In sorting centres, scales are commonly placed on platforms with few supports. Despite its multiple advantages, such construction is more prone to vibrations that affect weighing precision, leading to higher calibration values and significant loss of revenue over time. In order to find the optimal solution to this problem, it is necessary to analyse the environment and factors that affect the weighing results.

To provide a viable solution to this issue, we have designed a state-of-the-art mobile diagnostic system – the D-Box. This compact tool can reliably determine achievable weighing accuracy and calibration values of your conveyor scales. The procedure is quite straightforward: Our specialists will place the D-Box in a designated location for the scale installation. The tool will then calculate potential weighing accuracy values based on the application conditions and specified parameters such as speed, throughput rates and parcel sizes.

This solution offers essential information for better decision making, which is especially useful when modifying the platform design in sorting facilities or considering new integration or replacement of scales. Would you like to know how you can lower scale calibration values and improve the weighing accuracy in your specific application? Request an individual consultation with one of our experts.

Achieving maximum weighing accuracy in any application

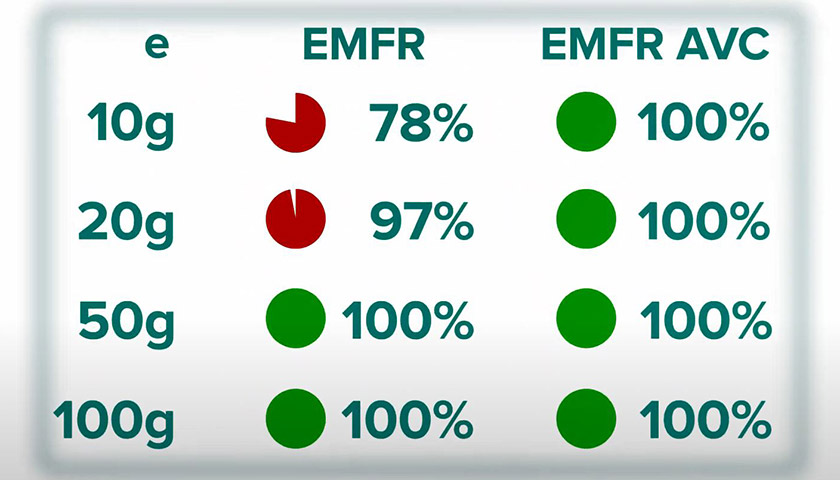

Based on analysis results made with the D-Box, you can decide whether the achievable weighing accuracy values fulfil your requirements. If the estimated impact of vibrations on weighing results is too big, integrating catchweighers with Active Vibration Compensation (AVC) technology will help to sidestep this problem.

While installation of additional supports for the platform can decrease the vibrations, it results in higher costs and blocks roadways. Integrating catchweighers with AVC technology instead maximises weighing precision despite the environment-specific challenges and eliminates the need for extra supports. Due to its innovative technology, AVC reduces the negative impact of vibrations on weighing results and lowers calibration values, leading to more accurate weight-based billing and higher profit margins.

Analysing data for smarter decision-making

Reliable prediction of weighing accuracy with the D-Box is an innovative service, the goal of which is to help you make an informed decision about the choice of scales for your specific application. By deploying the D-Box, your project team will be able to predict the accuracy of scales with or without AVC and compare the results. This provides them with an opportunity to choose an appropriate weighing system, thus reducing the risk of setting higher calibration values when the platform or a sorting plant is commissioned.

By deploying the D-Box, your project team will be able to predict the accuracy of scales with or without AVC and compare the results. This provides them with an opportunity to choose an appropriate weighing system, thus reducing the risk of setting higher calibration values when the platform or a sorting plant is commissioned.

The application experience

The simulation of AVC technology with the D-Box has already proven its worth in lighthouse projects with market leaders in parcel delivery.

In high-performance parcel centres with sorting capacities of 50,000 parcels per hour, prediction of scale accuracy with the D-Box revealed possibilities for optimisation of the platform construction. It showed that using catchweighers with AVC technology resulted in considerable improvements in weighing results. This information enabled companies to build platforms with fewer supports to leave driveways free.

The application experience demonstrates that the information produced by the D-Box leads to smarter decisions about ways to lower the operational disruption and the costs resulting from it.

Discover additional information about the technology, our services and benefits for your application in the D-Box flyer.