Your dynamic checkweigher with high-precision and ultra-fast weighing technology from Wipotec

As a leading manufacturer of checkweighers, Wipotec presents a world where accuracy meets speed: Our dynamic checkweighers combine cutting edge weighing technology with unsurpassed weighing accuracy. All our checkweigher systems are not only calibrated for quality, but also designed to excel in a variety of applications. The reliability of our checkweighers redefines the standard of a weighing system and guarantees outstanding performance even at maximum speeds.

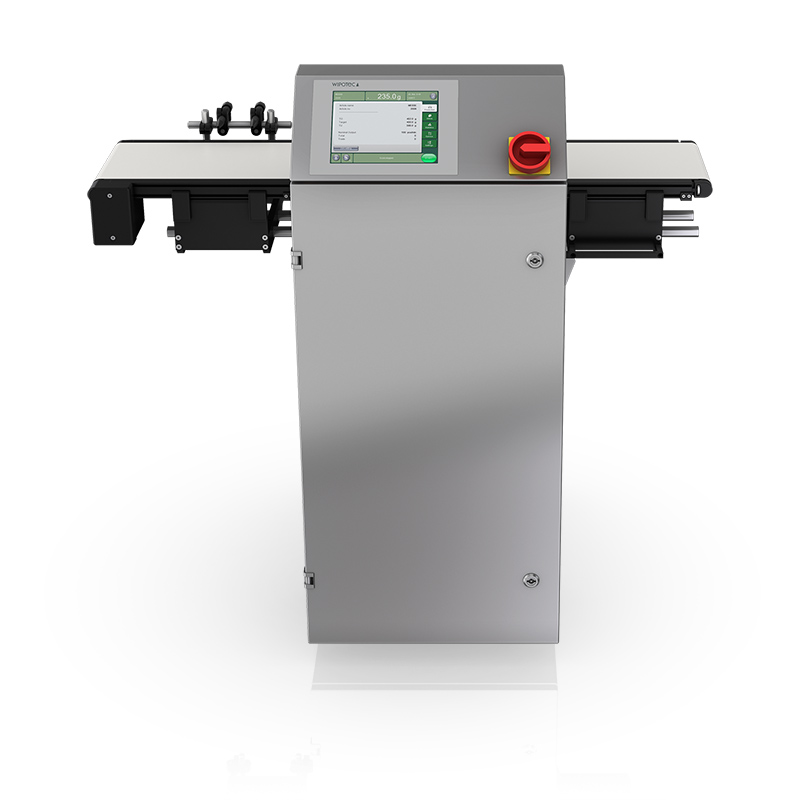

The E-M-A checkweigher series combines innovation with experience at the heart of our concept and is specially designed to enable exceptional throughput rates. These automatic checkweighers are the result of years of development in weighing technology and are customized to maximize the efficiency of your production lines. With a dynamic belt weigher from Wipotec, you are opting for a technology that assists you in optimizing processes sustainably while also guaranteeing the flexibility of your weighing system.

So, whether you need to avoid underfilling and overfilling or perform reliable end-of-line inspection, our calibrated checkweighers pass the test with flying colors. As your partner, we understand the importance of working together to deliver customized checkweigher solutions tailored to your needs. Over 30,000 checkweighers from Wipotec are in use around the world in sectors such as food, pharmaceuticals and cosmetics, helping to increase productivity and meet the highest quality standards every day.

Purchasing E-M-A checkweighers: Investing in the future

- Calibrated EMFR weighing technology for throughputs of up to 650 pc/min

- Precise filling results to reduce your overall TCO

- Easy, user-friendly operation included

- GMP conformity and hygienic design as standard

- Demand-orientated weighing system for tailor-made applications

Choose your checkweigher solution

We are constantly expanding our range of dynamic checkweighers by adding new modules. In addition to optical inspection and weighing control, your automatic belt weigher can also reliably detect foreign bodies in the product flow, for example. You always determine the precise design of your weighing solution. We supply the appropriate weighing technology.

The centerpiece of our range is the E-M-A series, combining maximum weighing accuracy with high speed. Our checkweighers offer perfect product handling for all sectors, dimensions and packaging types. Talk to us about your application. At Wipotec, every inline checkweigher is calibrated and meets both the legal requirements and applicable standards. Find your ideal dynamic weighing system now:

- Entry-level version of our dynamic checkweighers

- Familiar reliable quality assurance

- Compact integration of weighing solutions

- Intuitive operation via touch display

- Calibrated checkweigher for throughputs of up to 150 pc/min

- Our best-selling dynamic scales worldwide

- Optimized for medium speeds

- 100 % product monitoring in accordance with Pre-Packaging Ordinance

- Available as a Wash Down weighing system in IP69K

- With throughput rates of up to 250 pc/min

- The flagship Wipotec checkweigher system

- Maximum reliability, precision and speed

- Unlimited modularity of the dynamic weighing system

- Suitable for complex multilane applications

- Output calibrated for up to 650 pc/min

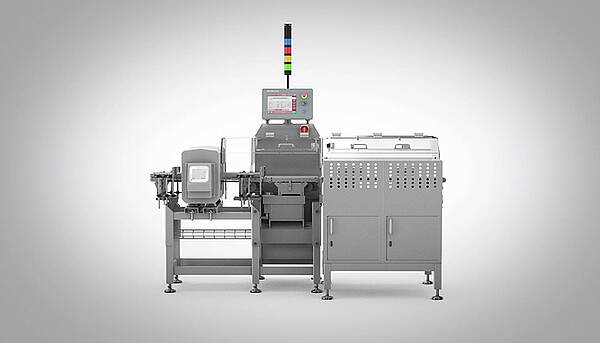

Metal detector in combination with checkweigher

Detecting foreign bodies within packaging is vital to ensure the highest quality standards. Legal texts such as the Pre-Packaging Ordinance thus ensure that metal detection remains mandatory. Particularly in industries such as the food sector, where products are delivered directly to the consumer for consumption, inspection and weighing technology has to be accurate.

No problem with Wipotec. We offer numerous weighing systems with integrated metal detectors. This is therefore fully integrated into the other modules and the weighing software and can be activated via the central HMI. Depending on the specific application, various ejection systems complement your Wipotec inline checkweigher, which automatically eject contaminated and incorrectly weighed products separately.

Selected media

Automatic checkweighers in food production

Food must always be handled correctly. You cannot afford any errors in weighing accuracy or product inspection during production. For this reason, a high-precision checkweigher is always an essential feature at the end of the line. Because only a dynamic weighing system can reliably prevent underfilling and overfilling at constantly fast speeds. Otherwise, you will be wasting money if the packs always contain more than necessary.

On the other hand, persistent underfilling significantly damages how others perceive your brand, which is why inaccurate weighing checks also damage your image and result in recalls. The right weighing technology must therefore be equipped for all conditions. Whether you produce ready meals, confectionery or baby food, Wipotec checkweighers have you covered. Your dynamic checkweigher is calibrated and can be equipped with a metal detector or the latest X-ray technology to detect foreign bodies.

Maximum safety thanks to pharmaceutical checkweigher

Strict guidelines also apply to checkweighers in the healthcare sector. Wipotec checkweighers are designed for this by default. In addition, pharmaceutical companies in particular are subject to strict rules regarding drug safety. Our weighing systems help to control dosages and weigh medicines precisely to the milligram.

Whatever packaging formats you use, we adapt the weighing technology perfectly to your needs. Even unpackaged medicines or other low-weight products are reliably recorded by your dynamic belt weigher. In addition, continuous labeling is no longer a dream of the future.

Dynamic checkweighers with innovative Wash Down hygienic design

Wipotec checkweighers easily meet the strict hygiene requirements of sectors such as the food industry. Our high-precision weighing solutions are made of stainless steel and are equipped for protection classes up to IP69K according to requirements. Your checkweigher thus meets legal requirements and also protects your products’ integrity and your customers’ well-being.

The robust construction and hygienic design of the dynamic weighing technology reinforce its suitability for areas with frequent and intensive cleaning cycles. Thanks not least to these quality features, Wipotec inline checkweighers have for years been firmly established in the production halls of many well-known food manufacturers, for example for meat and cold meat products or dairy products.

Wipotec weighing technology – technology that makes the difference

The outstanding quality of our automatic weighing systems is due in particular to the use of our own core technologies and components. As a manufacturer, we achieve a vertical integration of more than 80 % for our dynamic checkweighers.

Examples include our market-leading EMFR Weigh Cells, vibration-compensating AVC technology and IMOT servomotors, which, when combined with many other hardware and software factors, make the Wipotec checkweigher unique.

Advantages of ease of use and networking

Wipotec’s dynamic weighing technology is simple and intuitive to use. Your production data is recorded seamlessly. Our customized software solution networks the Wipotec checkweighers in your production line and enables connection to other inspection systems from our range.

Now link your foreign body inspection with the checkweigher using the X-ray scanner under a single centralized interface. The calibrated weighing system also allows automatic ejection as part of the belt weigher.

In this way, we provide the basis for a perfectly networked production area as the basis for your reliable statements. Your quality assurance begins right here.

High-speed throughput and calibrated checkweigher – your Wipotec weighing system

If your production is operating at top speed, you need checkweighers that won’t slow you down. As an experienced checkweigher manufacturer, we never neglect weighing accuracy, even in high-speed applications. As the example of our partner Manner demonstrates in an impressive way, throughput rates of up to 640 items per minute can be achieved permanently.

So you can immediately move into the fast lane when you purchase our dynamic checkweigher. We are happy to cater to individual wishes. For companies in the cosmetics industry, for example, we have customized solutions for cylindrical or wobbly items that are handled safely using a rotary star wheel. Whatever weighing technology you prefer, we have the right system for your business. Guaranteed.

Find the right dynamic checkweigher for you

Do you need an automatic weighing system that performs other tasks in addition to weighing control? A Wipotec checkweigher can easily be supplemented with specific units. In the following list, you will find the most popular models of our checkweighers, from simple belt weighers to comprehensive weighing systems. Of course, we also offer individually equipped dynamic checkweighers on request, always calibrated and prepared for use at the end of the line. Trust the latest weighing technology from Wipotec.

FAQ on dynamic checkweighers

What is a dynamic checkweigher?

Dynamic checkweighers are indispensable in modern production facilities. Primarily, they are used to determine weights accurately in throughput, for example of individual items or packaging of various dimensions that has already been aggregated. Calibrated checkweigher systems are therefore a vital element in quality assurance at the end of the production line. Your company benefits from making an important part of the production process considerably more efficient thus making the entire production more effective.

The key parameters of the underlying weighing technology are thus achievable weighing accuracy combined with the possible speed of your checkweigher. In short, you need exactly the right dynamic weighing system for your application. This is the only way to achieve the conditions set by both the market and legislators in the long term. At Wipotec, we therefore rely on automatic checkweighers that are extremely efficient and durable. With the appropriate service included, of course.

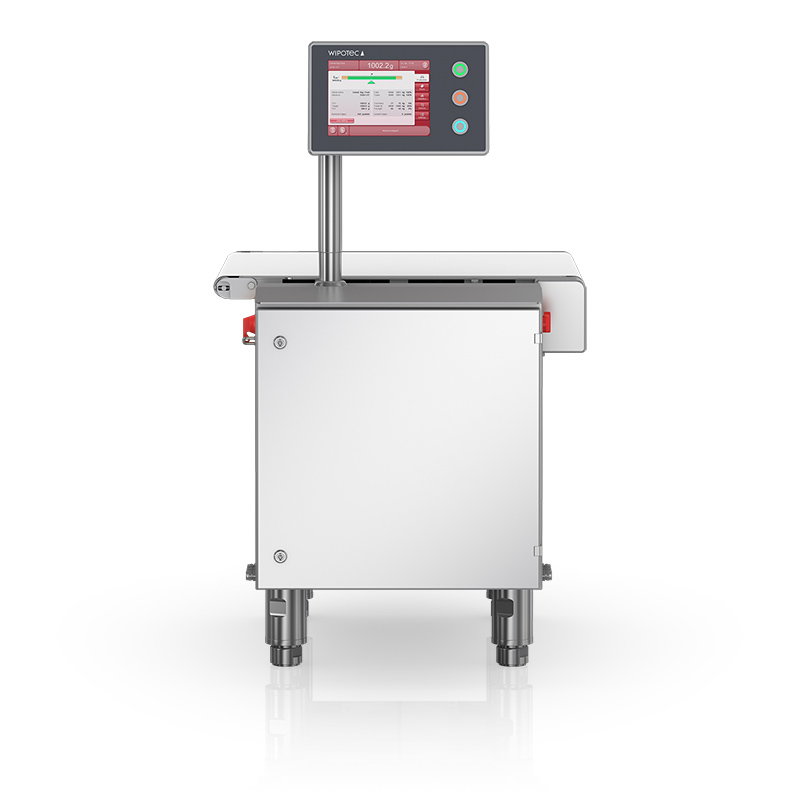

How is a belt weigher constructed?

In the standard version, a dynamic checkweigher consists of various belts for transport, handling and weighing control, which are usually integrated into your production line at the end. In addition, every Wipotec weighing system includes other components that ensure a smooth process:

- First, products are fed via a conveyor belt, including units for separating the products.

- The high-precision Weigh Cells of our dynamic scales are based on the principle of electromagnetic force restoration (EMFR).

- Directly linked to the weighing technology is the ejection system, which gently rejects items of incorrect weight.

- You can view the results in real time via a central user interface using a touchscreen.

Thanks to the inherent flexibility of our checkweigher solutions, you can add additional modules to these basic elements at any time if your application so requires. In the food sector, for example, a metal detector is mandatory. Manufacturers also often carry out X-ray inspections to detect all foreign bodies without fail.

Which industries particularly benefit from the use of dynamic checkweighers?

As an experienced manufacturer of checkweighers, over the years we at Wipotec have produced well over 30,000 weighing solutions for applications in numerous industries. Our dynamic weighing technology covers a wide range of segments. The checkweigher systems can reliably handle both large and small, light and heavy, flat and round, stable and wobbly products – and everything in between. Our specialists have met every challenge to date.

Dynamic checkweighers from Wipotec are in constant use in the following industries, among others:

- Food and drink

- Pharmaceuticals

- Cosmetics

- Chemical industry

- Construction material and minerals

- Other technical applications

Even the most extreme conditions do not deter our reliable checkweighers. Does your production include potentially explosive atmospheres? We have the ideal solution for aerosols. Do you have to meet specific hygiene requirements? Our weighing systems are made of stainless steel with a specially developed Wash Down hygienic design. Even in environments prone to vibration, your Wipotec checkweigher can easily cope and achieve accurate results thanks to AVC technology. This is the future of dynamic weighing systems.

How much does a dynamic checkweigher cost?

It is difficult to give a standard answer to this question. The exact price composition of a dynamic weighing system depends on many factors – primarily on the requirements of your production. We have more cost-effective entry-level versions of the EC-E series for throughputs of up to 150 pc/min, which nevertheless weigh with the usual precision. In the medium application range, on the other hand, the proven weighing technology of the HC-M series enables an output of 250 pc/min and comes with other additional features. But for maximum precision at speeds of up to 650 pc/min, we can only recommend our premium model HC-A.

So if you wish to purchase a dynamic checkweigher, you’ve come to the right place. We are committed to the highest quality standards, which are evident in every element of our checkweighers. This means that the purchase of a weighing system quickly pays for itself. Do you want to receive a personalized offer? Then send us your inquiry today. Together we will certainly find the right checkweigher solution for your business. This is because the modularity inherent in our weighing systems ensures maximum flexibility in terms of the configuration you require. We’ve got you covered.

What is the difference between static and dynamic checkweighers?

A calibrated checkweigher should always provide precise measured values. The difference between static and dynamic weighing technology lies rather in how the weighing process is carried out:

- Static scales are only suitable for weighing stationary objects. An operator has to be present for the entire process, place the product on the weighing cell, record the results and then prepare the next cycle. Weighing systems of this kind are thus manual and highly labour-intensive in day-to-day operation. In addition, only individual articles are randomly checked. On the other hand, static weighing systems are robust and often extremely easy to maintain.

- Dynamic checkweighers, on the other hand, adapt to the product in the product flow. This allows you to ensure 100 % inspection of all items passing through, as no package escapes the right checkweigher. Weighing control is thus integrated into your production process and functions entirely automatically. Other modules perform tasks such as ejection or optical inspection, which would otherwise have to be performed by an operator. This allows you to reduce your personnel expenses and save on costs.

Both variants therefore have their advantages. So we do not want to make the decision for you. In addition to a wide range of dynamic weighing systems, we also offer static solutions such as our high-precision HC-M-NSW.